FX-2000

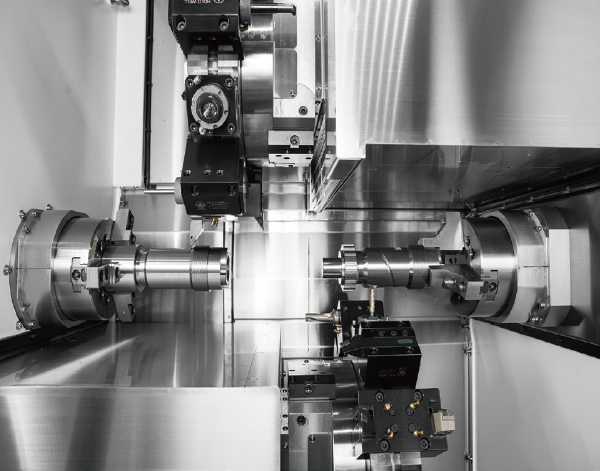

The configuration of the new generation FX-1500, FX-2000series dual-turret, dual-spindle multi-tasking center is various.

The upper and lower turrets can be individually selected for Y-axis or milling functions. The bed is slanted with a 60-degree angle, and through finite element analysis (FEA) and practical experience design, which shown a better ability to suppress thermal displacement, remove chips, and reduce the floor space requirement.

The flexibility of tool position and processing sequence is improved with the both of the upper and lower Y-axes' configuration.

The upper and lower turrets can be individually selected for Y-axis or milling functions. The bed is slanted with a 60-degree angle, and through finite element analysis (FEA) and practical experience design, which shown a better ability to suppress thermal displacement, remove chips, and reduce the floor space requirement.

The flexibility of tool position and processing sequence is improved with the both of the upper and lower Y-axes' configuration.

- Specification

Simultaneous Turning and Milling with Upper and Lower Turret

Both of the upper and lower turret can individually proceed with milling and drilling on the single side spindle at the same time, which means the configuration is flexible for tool positioning between both of turrets. In this case, it can short idle times and improve productivity.

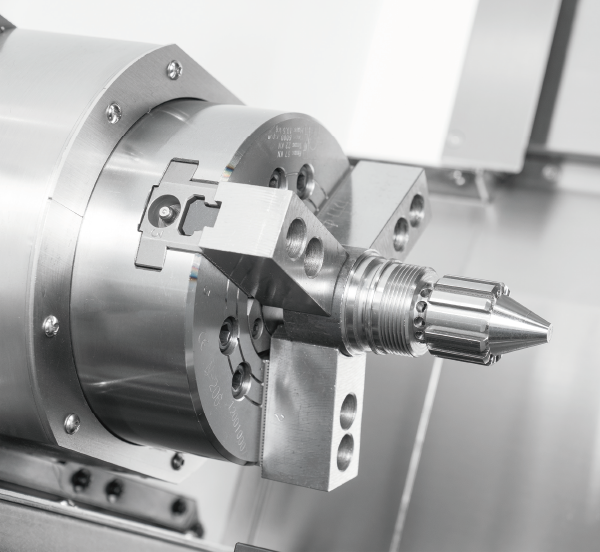

Spindle

Since the spindle is made in-house, there is no doubt about the quality and reliability.

The design of the headstock body had a symmetry, which is reducing the thermal deformation influence of machining accuracy. The spindle is driven by a belt, that is the most economical and simple for maintenance.

There are various options open to spindle. For the main spindle, there are three specifications of the through-hold diameter: Ø56, Ø63,Ø76; for the sub-spindle, are two specifications Ø56 and Ø63.

The design of the headstock body had a symmetry, which is reducing the thermal deformation influence of machining accuracy. The spindle is driven by a belt, that is the most economical and simple for maintenance.

There are various options open to spindle. For the main spindle, there are three specifications of the through-hold diameter: Ø56, Ø63,Ø76; for the sub-spindle, are two specifications Ø56 and Ø63.

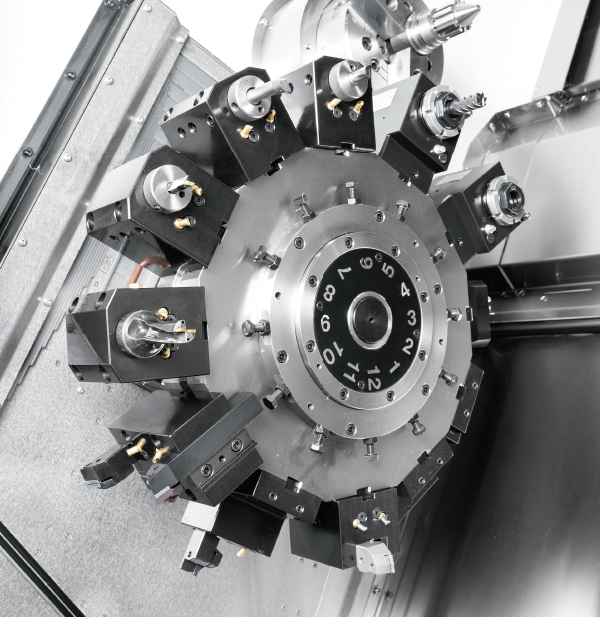

Turret

High rigidity and high precision are characterized by the T12 milling turret of TAIWAN TAKISAWA. It can perform multiple and complex machining, such as, turning, milling, drilling, and tapping, etc., which improving the productivity and the machining accuracy.

There is also a turning turret available as an option.

There are two types of tooling system available from TAIWAN TAKISAWA: STANDARD ER20, or BMT45.

There is also a turning turret available as an option.

There are two types of tooling system available from TAIWAN TAKISAWA: STANDARD ER20, or BMT45.

| Item | Unit | FX-2000 | FX-2000M2 | FX-2000Y | FX-2000Y2 | |

|---|---|---|---|---|---|---|

| Capacity | Max. Swing | mm | 220 | 220 | 220 | 220 |

| Max. Turning Diameter | mm | 220 | 220 | 220 | 220 | |

| Max. Turning Length | mm | 535 | 535 | 535 | 535 | |

| Spindle | Max. Bar Work Capacity | mm | 52(65)/42(52) | 52(65)/42(52) | 52(65)/42(52) | 52(65)/42(52) |

| Spindle Speed | rpm | 5000(4500)/6000(5000) | 5000(4500)/6000(5000) | 5000(4500)/6000(5000) | 5000(4500)/6000(5000) | |

| Chuck Size | inch | 6"/6" | 6"/6" | 6"/6" | 6"/6" | |

| Spindles | 2 | 2 | 2 | 2 | ||

| Turret | Turret Type | T12(T24)/T12(T24) | T12(T24)/T12(T24) | T12(T24)/T12(T24) | T12(T24)/T12(T24) | |

| Live Tool Turret(Y/N) | Y | Y | Y | Y | ||

| Axis | Y Axis(Y/N) | N | N | Y | Y | |

| Machine Dimension |

Height | mm | 2077 | 2077 | 2077 | 2077 |

| W×D (Right-disposal Chip Cnv.) |

mm | 3850×2173 | 3850×2173 | 3850×2173 | 3850×2173 | |

| W×D (Rear-disposal Chip Cnv.) |

mm | 3090×3008 | 3090×3008 | 3090×3008 | 3090×3008 | |

| Weight | kg | 9200 | 9300 | 9400 | 9500 | |

| Item | Unit | FX-2000 | FX-2000M2 | FX-2000Y | FX-2000Y2 | |

|---|---|---|---|---|---|---|

| Capacity | Max. Swing | inch | 8.66 | 8.66 | 8.66 | 8.66 |

| Max. Turning Diameter | inch | 8.66 | 8.66 | 8.66 | 8.66 | |

| Max. Turning Length | inch | 21.06 | 21.06 | 21.06 | 21.06 | |

| Spindle | Max. Bar Work Capacity | inch | 2.05(2.56)/1.65(2.05) | 2.05(2.56)/1.65(2.05) | 2.05(2.56)/1.65(2.05) | 2.05(2.56)/1.65(2.05) |

| Spindle Speed | rpm | 5000(4500)/6000(5000) | 5000(4500)/6000(5000) | 5000(4500)/6000(5000) | 5000(4500)/6000(5000) | |

| Chuck Size | inch | 6"/6" | 6"/6" | 6"/6" | 6"/6" | |

| Spindles | 2 | 2 | 2 | 2 | ||

| Turret | Turret Type | T12(T24)/T12(T24) | T12(T24)/T12(T24) | T12(T24)/T12(T24) | T12(T24)/T12(T24) | |

| Live Tool Turret(Y/N) | Y | Y | Y | Y | ||

| Axis | Y Axis(Y/N) | N | N | Y | Y | |

| Machine Dimension |

Height | inch | 82 | 82 | 82 | 82 |

| W×D (Right-disposal Chip Cnv.) |

inch | 152×86 | 152×86 | 152×86 | 152×86 | |

| W×D (Rear-disposal Chip Cnv.) |

inch | 122×118 | 122×118 | 122×118 | 122×118 | |

| Weight | lb | 20285 | 20505 | 20726 | 20946 | |